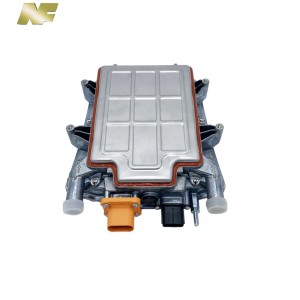

NF 7KW DC600V PTC High voltage Coolant Heater for electric vehicle

Technical Parameter

| Item | W09 PTC coolant heater |

| Medium temperature | -40℃~90℃ |

| Medium type | Water: ethylene glycol /50:50 |

| Power/kw | 7kw |

| Rated voltage(VDC) | 600 |

| Working voltage(VDC) | 450-750 |

| Rated power(kW) | 7(1±10%)@10L/min,T_in=60℃,600V |

| Impulse current(A) | ≤25@750V |

| Controller low voltage(VDC) | 9-16 or 16-32 |

| Control signal | CAN2.0B、LIN2.1 |

| Control model | Gear (5th gear) or PWM |

Product Size

Description

This PTC electric heater is suitable for use in electric, hybrid, and fuel cell vehicles and serves primarily as the main heat source for cabin temperature regulation. It is compatible with both driving and parking modes of operation. During the heating process, electrical energy is efficiently converted into thermal energy through PTC components. As a result, this product delivers faster heating performance compared to conventional internal combustion engines. Additionally, it can be used for battery temperature regulation—specifically for heating the battery to its optimal operating temperature—as well as for fuel cell startup loads.

1. High-voltage electric vehicle PTC heater

The high-voltage electric vehicle PTC heater is an advanced heating system specifically designed for electric buses. PTC stands for Positive Temperature Coefficient, which refers to the property of the heating element whose electrical resistance increases with rising temperature. This characteristic enables the PTC heater to self-regulate its output, ensuring stable and consistent heating performance for the battery system.

This heater employs state-of-the-art technology to provide efficient and safe battery heating. By operating on high-voltage power systems, it maintains an optimal temperature range even under extreme weather conditions. The system also incorporates enhanced safety features such as overtemperature protection and short-circuit prevention.

2. High-voltage liquid electric heater

In addition to PTC heaters, high-voltage liquid electric heaters represent another advanced technology for battery thermal management in electric vehicles. This system circulates a high-voltage liquid coolant throughout the battery pack, ensuring uniform and efficient heat distribution.

The liquid heating system consists of a network of precisely engineered channels embedded within the battery module. These channels allow the coolant to flow through and either absorb or dissipate heat, effectively preventing overheating and potential thermal damage. The heat transfer efficiency is further improved by using a specially formulated coolant with high thermal conductivity.

Compared to traditional air-based heating methods, electric liquid heaters offer several advantages. They are more energy-efficient, minimize heat loss, and provide superior control over battery pack temperature. These benefits contribute to improved vehicle performance, extended battery life, and enhanced overall system efficiency.

Conclusion

As the demand for electric buses continues to rise, ensuring the reliability and efficiency of battery systems becomes increasingly important. Advanced heating technologies such as high-voltage PTC heaters and high-voltage liquid electric heaters provide effective solutions to the challenges posed by extreme climatic conditions.

These innovative heating systems not only protect batteries from low-temperature damage but also ensure optimal performance and longevity. By actively managing battery temperature, they enhance passenger comfort and system reliability, while supporting the sustainability and environmental benefits of electric mobility.

With ongoing research and development in this field, further advancements and novel thermal management solutions are expected to emerge, making electric buses an increasingly viable, efficient, and convenient transportation option for the general public.

Advantage

The integrated circuit water heating heater performs the following core functions:

- Control Function: The heater supports dual control modes—power control and temperature control—to ensure precise and stable operation.

- Heating Function: Converts electrical energy into thermal energy with high efficiency.

- Interface Function: Facilitates the connection of the heating module and control module, including power input, signal input, grounding, as well as water inlet and outlet interfaces.

Application

Packaging & Shipping

Our Company

Hebei Nanfeng Automobile Equipment (Group) Co., Ltd is a group company with 5 factories, that specially produce parking heaters, heater parts, air conditioner and electric vehicle parts for more than 30 years. We are the leading auto parts manufacturers in China.

Our factory's production units are equipped with high tech machineries, strict quality,control testing devices and a team of professional technicians and engineers endorsing the quality and authenticity of our products.

In 2006, our company has passed ISO/TS16949:2002 quality management system certification. We also bagged the CE certificate and Emark certificate making us among the only few companies in the world acquiring such high level certifications.

Currently being the largest stakeholders in China, we hold a domestic market share of 40% and then we export them around the globe particularly in Asia, Europe and Americas.

Meeting the standards and demands of our customers have always been our top priority. It always encourages our experts to continuously brain storm, innovate, design and manufacture new products, impeccably suitable for the Chinese market and our customers from every nook of the world.

FAQ

1. What is an electric bus battery heater?

The electric bus battery heater is a device used to regulate the temperature of the electric bus battery. It helps maintain the optimal operating temperature of the battery, especially in cold weather conditions, to ensure its efficiency and longevity.

2. Why do electric buses need battery heaters?

Electric bus batteries can be affected by extreme temperatures, especially in cold weather. Low temperatures can significantly reduce battery performance and overall range. Battery heaters are critical to preheating the battery and maintaining its temperature within an optimal range to ensure reliable operation and maximize bus efficiency.

3. How does the electric bus battery heater work?

Electric bus battery heaters typically use a combination of heating elements and temperature sensors to monitor and regulate the temperature of the battery. When the ambient temperature falls below a certain threshold, the heater kicks in and warms the battery. Temperature sensors help regulate heat output and maintain the desired temperature range.

4. What are the benefits of using battery heaters on electric buses?

There are several advantages to using battery heaters in electric buses. It helps maintain battery performance and range even in cold weather conditions. By keeping the battery within an optimal temperature range, the heater ensures efficient energy transfer and extends the battery's service life. It also reduces the risk of cold-start issues and enables faster charging in cold climates.

5. Can the electric bus battery heater be used in hot weather?

While the primary function of electric bus battery heaters is to heat the batteries in cold weather, some advanced systems can also cool the batteries in hot weather conditions. This helps prevent overheating and ensures optimal battery performance regardless of ambient temperature.

6. Will using a battery heater increase energy consumption?

While electric bus battery heaters do consume additional energy, they are a key component that help maintain battery efficiency, especially in cold weather. The energy consumed by the heater is insignificant compared to the overall energy needs of the bus, and the benefits far outweigh the additional energy consumption.

7. Can existing electric bus models be equipped with battery heaters?

Yes, battery heaters can often be retrofitted into existing electric bus models. Different manufacturers offer retrofit solutions that can be integrated into existing battery management systems. It is important to ensure compatibility as each bus model may have different installation requirements.

8. How much does a battery heater for an electric bus cost?

The cost of an electric bus battery heater can vary based on a variety of factors including battery size, system complexity and brand. Generally speaking, the cost can range from a few thousand dollars to tens of thousands of dollars.

9. Are electric bus battery heaters environmentally friendly?

Battery heaters for electric buses contribute to the overall sustainability and environmental friendliness of electric vehicles. By maintaining optimal battery temperatures, they increase the energy efficiency of buses, reducing the need for additional charging and minimizing energy waste. In addition, efficient battery heating allows for better utilization of mileage and reduces the overall carbon footprint of electric bus operations.

10. Are there any safety issues with electric bus battery heaters?

Battery heaters for electric buses are designed with safety in mind. They are rigorously tested and adhere to stringent safety standards to ensure their reliable, safe operation. Temperature sensors, overheating protection features and insulation mechanisms are often integrated into these systems to prevent any safety hazards.